This comprehensive comparison compares the differences between fiber and diode lasers. Find out which one is better suited for your business needs.

Laser technology is crucial in various industries, from manufacturing to medical applications. As businesses strive to improve efficiency and precision, understanding the differences between different types of laser systems becomes essential.

This post will discuss the critical distinctions between fiber and diode lasers, exploring their advantages and limitations. We’ll also help you determine which laser technology best suits your industry or application.

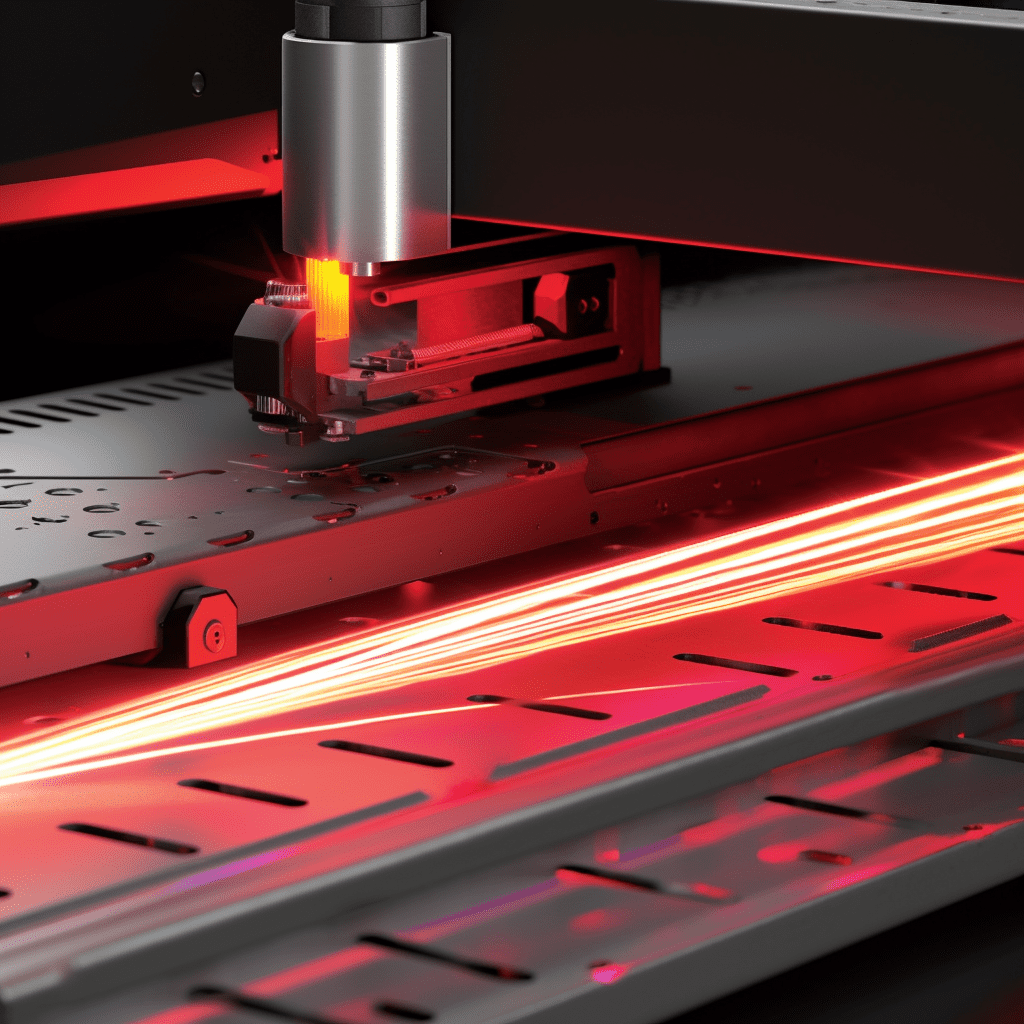

Fiber lasers are a solid-state laser technology that utilizes optical fiber as the active medium, doped with rare-earth elements such as erbium, ytterbium, neodymium, etc. The laser beam is generated within the fiber itself and transmitted through flexible optical fibers, providing superior beam quality and stability.

Some key benefits of fiber lasers include:

Fiber lasers can produce high output power, allowing them to cut, weld, or process a wide range of materials, including thin sheets and reflective metals. Their high power density enables faster processing speeds and improved productivity.

Fiber laser machines are used in various industries and applications, such as:

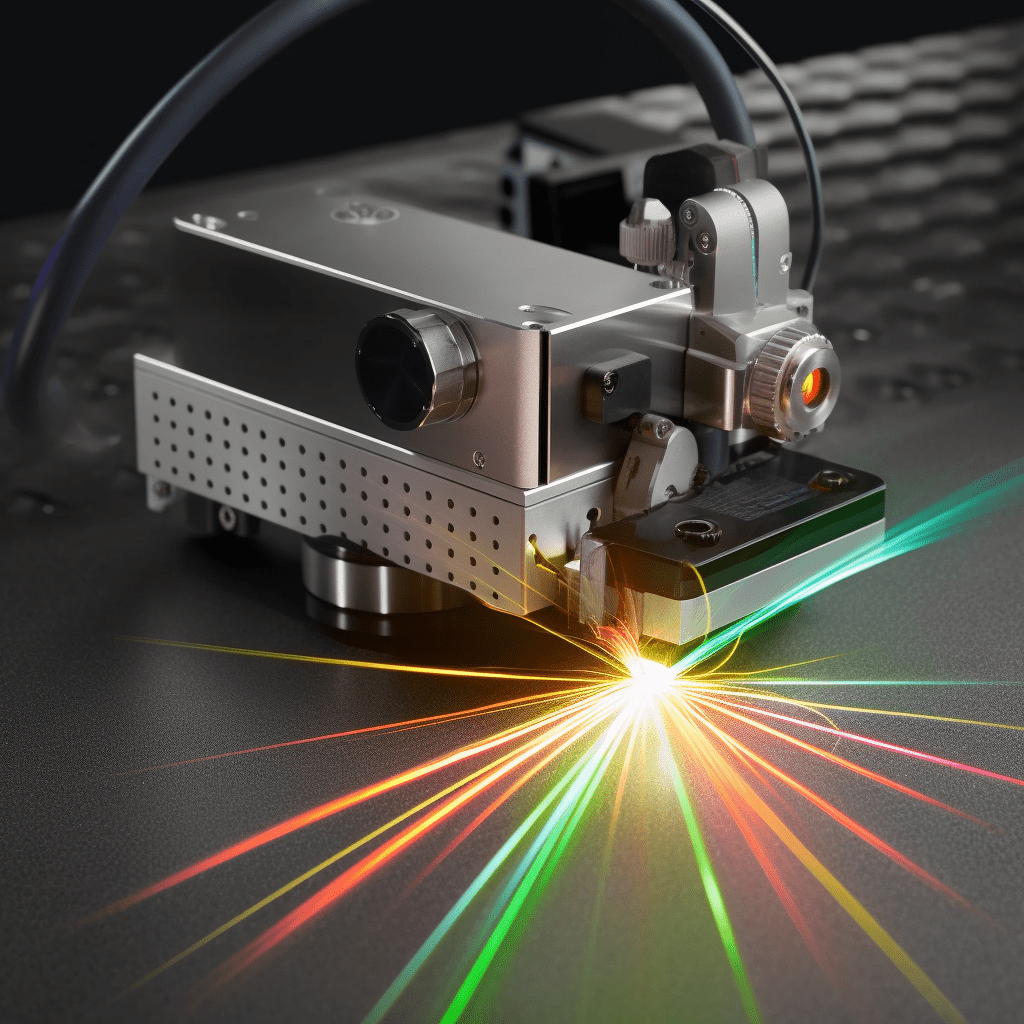

Diode lasers are semiconductor lasers that use a diode, typically made of gallium arsenide or other semiconductor materials, as the active medium. When an electric current is applied to the diode, electrons, and holes, recombine, resulting in the emission of photons and the generation of a laser beam.

The diode laser operation involves:

Some key benefits of diode lasers include the following:

Diode lasers are used in a variety of industries and applications, such as:

| Feature | Fiber Laser | Diode Laser |

| Laser Beam Quality | Excellent, near-diffraction-limited beam | Good, but typically lower than fiber lasers |

| Light Source | Optical fiber doped with rare-earth elements | Semiconductor diode |

| Cutting Efficiency | High efficiency, suitable for a wide range of materials | Lower efficiency, suitable for thin materials |

| Laser Modules | Compact design, easy to integrate into existing systems | Very compact, ideal for portable applications |

| System Maintenance | Low maintenance due to fewer components | Low maintenance, long operational life |

| Power Output | High output power, suitable for heavy-duty applications | Lower output power, suitable for less demanding tasks |

This table highlights the key differences between fiber lasers and diode lasers, including laser beam quality, light source, cutting efficiency, laser modules, system maintenance, and power output. By comparing these features, you can better understand which type of laser technology is more suitable for your specific needs and applications.

When comparing fiber lasers with other laser types, it’s essential to understand the basic principles and working mechanisms to determine which technology best suits your needs. Below are brief comparisons of fiber lasers with CO2, disk, solid-state, and laser pointers.

CO2 laser cutters utilize a gas mixture as the active medium, primarily consisting of carbon dioxide, and generate an infrared laser beam. CO2 lasers are widely used in material processing, cutting, and engraving applications.

Disk lasers are a type of solid-state laser that employs a thin disk made from ytterbium-doped yttrium aluminum garnet (YAG) or other materials as the active medium. Disk lasers deliver high output power and excellent beam quality, making them suitable for various material processing tasks.

Solid-state lasers use a solid, crystalline, or glass material doped with ions as the active medium, and the laser beam is generated through the process of stimulated emission. Examples of solid-state lasers include Nd: YAG, ruby, and Ti: sapphire lasers.

Laser pointers are handheld devices that emit a low-power laser beam, often used for presentations or recreational purposes. Most laser pointers use diode lasers as their light source due to their compact size and low power consumption.

When selecting a laser for your specific needs and applications, evaluating various factors is crucial to ensure you choose the most suitable technology. Here are some important aspects to consider when selecting a laser:

Wall plug efficiency refers to the conversion of input electrical power into useful laser output. A higher wall plug efficiency means the laser can generate more output power with less input power, resulting in lower energy consumption and operational costs. Comparing the wall plug efficiency of different lasers can help you choose a more energy-efficient and cost-effective solution.

The output coupler is a partially reflective mirror that forms one end of the laser cavity, allowing a portion of the laser beam to exit while reflecting the rest back into the cavity. The characteristics of the output coupler, such as reflectivity and transmission, can significantly impact the performance of the laser.

When selecting a laser, consider the output coupler’s type and specifications to ensure optimal application performance.

Beam quality is a critical factor in determining a laser’s overall performance and capabilities. A high-quality laser beam will have a near-diffraction-limited profile, enabling better precision, cutting capabilities, and processing speeds. When comparing lasers, evaluate their beam quality to ensure you select a laser that can deliver the precision and performance required for your specific tasks.

If you plan to use the laser for engraving purposes, it’s essential to consider the engraving capabilities of the laser system. These capabilities may include the type of materials that can be engraved, the engraving resolution, and the maximum engraving speed. Different laser systems’ engraving capabilities can help you select the most suitable technology for your engraving needs.

In conclusion, when comparing fiber lasers and diode lasers, it’s essential to consider factors such as performance, efficiency, customization, and return on investment. Fiber lasers tend to excel in areas like precision, speed, and adaptability, making them a popular choice for many industries.

However, the final decision should be based on your specific needs and applications. Explore other resources on our website to learn more about laser technology and how it can benefit your business.

Experience unparalleled efficiency and precision with Baison‘s cutting-edge fiber laser technology. Our commitment to quality, innovation, and customer satisfaction ensures you receive the best solutions for your business needs. Contact our experts to find the perfect laser system tailored to your requirements.